There’s no doubting that the UK is increasingly subject to extreme rainfall events, regardless of the arguments about the nature and causes of climate change. These extreme rainfall events put the UK’s infrastructure under great pressure, and urban and suburban flooding is now much more frequent.

According to the Environment Agency, more than 5 million homes in England and Wales are at risk of flooding – a point grimly made only this December, when the agency issued 79 flood warnings for the south, Midlands, east and Yorkshire. Worst hit was Hayle in Cornwall, where a ‘major incident’ was called after 50 homes and businesses went under water; while parts of the M23 near Crawley were closed, disrupting access to Gatwick Airport.

The crucial need to contain and control rainfall – to protect people and property – is leading to more stringent legislation and standards; impacting upon public authorities, developers and contractors and the design elements necessary to better manage these extreme events.

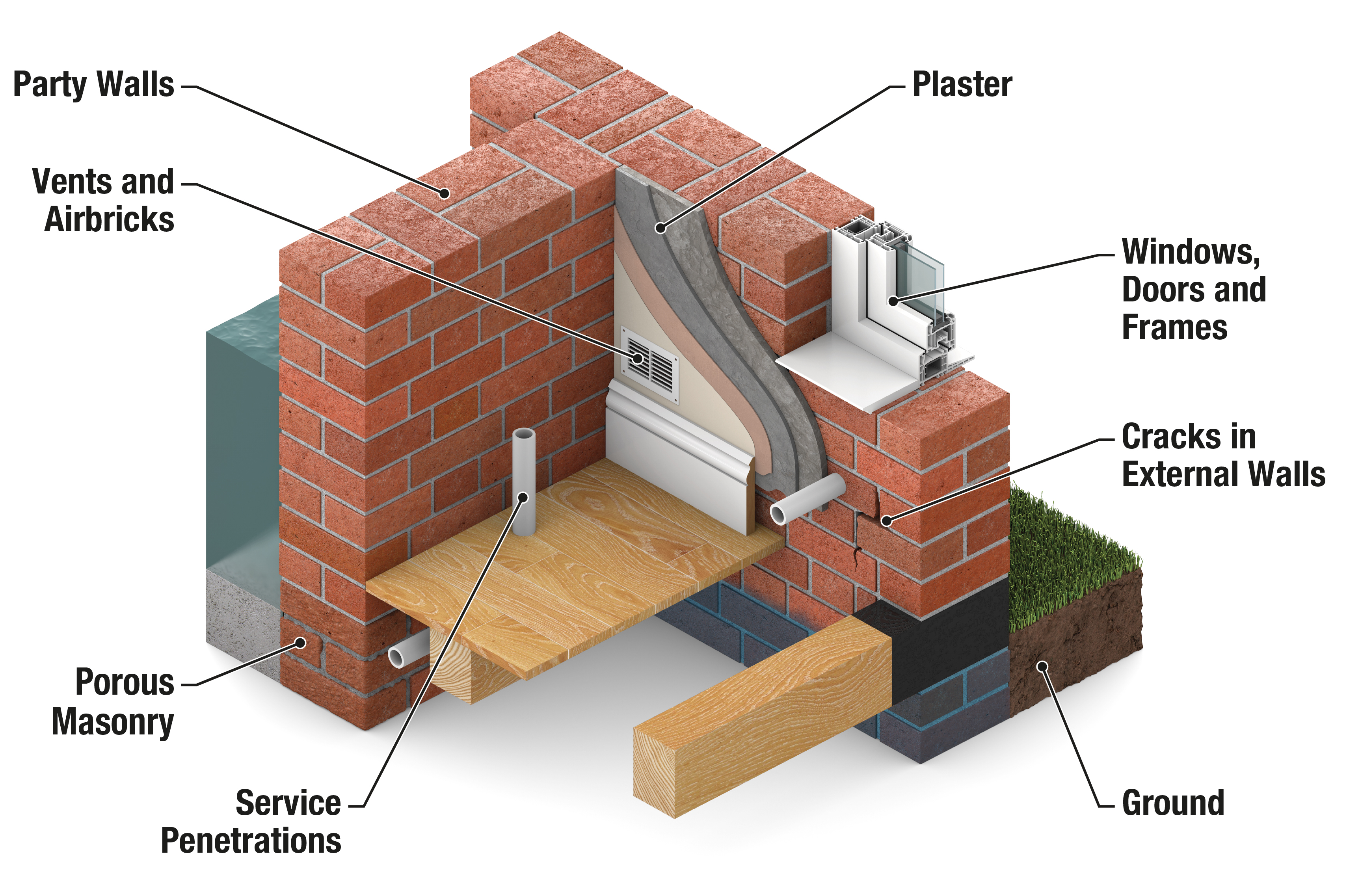

Flood Vulnerabilities

It has been the case that design solutions for flooding were described as either ‘flood resistant’ or ‘flood resilience’.

However, use of these terms has become muddled. Consequently, less equivocal terms are now being employed: ‘water-exclusion strategy’ (i.e. resistance), and ‘water-entry strategy’ (i.e. resilience).

A ‘water-exclusion strategy’ aims to prevent water from getting into the building and cause damage. A ‘water-entry strategy’’ means constructing so that, although water may enter, the impact is lessened, structural integrity is maintained and drying and cleaning is made easier.

The likely extent of flooding will impact on the choice of design. When low water depths are expected, a ‘water exclusion strategy’ typically is recommended. A ‘water entry strategy’ is needed when higher water levels are likely: a difference in water level of over 0.6m between inside and outside can cause significant structural damage to standard masonry buildings.

In practice, a pragmatic combination of both is taken because it is often either prohibitively expensive or impractical to provide a completely flood-resistant building – especially in cases where flood protection is being retrofitted to existing buildings.

Designing in flood resistance

In a new-build situation, the best way to stop water penetrating is to ensure that all concrete used is waterproof and to seal all construction joints with specifically designed proprietary tapes. Services coming in through walls and floors should be designed to be watertight.

As a second line of defence, and if budget and circumstances allow, a cavity drainage membrane, such as Oldroyd, can help with the management of flood water. That membrane directs the water down the walls into a perimeter drain with the water running to a sump where it can be evacuated using a pump. This type of approach is also popular as a retrofit measure to existing buildings, used in combination with an upgrade of resistance to the existing masonry, such as tanking and repointing.

Designing in flood resilience

When designing for flood resilience, the goal is to make it as easy as possible to clean the interior of a house after a flood. Floors and walls should be finished with an easily cleanable surface such as tiles. If the floor surface isn’t water compatible it should be easy to take up and replace.

Water compatible doors and woodwork should also be considered. Electrical circuits and sockets should be situated above the expected water level and in a kitchen, appliances can be raised up off the floor.

Apart from floor coverings and joinery, decoration elements are likely to be hit the most – especially where walls are finished with gypsum or lime based plasters. A report from the University of Portsmouth – The Effect of Moisture on Plaster Performance – supports the use of damp-resistant plasters instead. This cost-effective system utilises breathable, moisture-resistant plasters to allow the fabric of a flooded building to dry out whilst providing a durable finish that will be resilient to future flooding. Moisture-resistant screeds have also been developed using similar technology.

After a flood, it is then possible to simply hose down and sterilise the wall. The make-up of these plasters means they have large pores and a high pore volume. This allows salts to form within the plaster rather than on the surface; and the high pore volume results in high water vapour diffusion (breathability) and higher thermal resistance, reducing the risk of condensation.

Vital details

Drawing upon its 35 years of experience, Safeguard has created several flood management systems that counteract the various ways by which flood water can enter a property, as well as detailing the internal and external remedial works necessary for habitable reinstatement.

The correct approach can be selected from three flood resilience systems, or a mixture of them, to anticipate every flood scenario.

The foundation for the system is Flood System 1, which applies to internal walls. This provides basic flood resilience through the use of damp-resistant plaster and a specially designed lime-based skim coat as wall coating, together with secondary chemical Damp Proof Course (DPC) rods installed above expected flood height.

Unlike traditional gypsum plasters, these plaster and skim finishes retain their strength and dimensions under flood conditions and dry out quickly, while their alkaline content deters mould growth.

The secondary DPC is formed using damp-proofing Rods in combination with liquid Damp Proof Membrane (DPM) that should be applied to seal floors and lap the wall to just above the level of the primary DPC.

Deploying two strategies (resilience combined with basic resistance), Flood System 2 adds a layer of protection to the external walls, by limiting the amount of water seeping through the walls and speeding up the drying time after a flood. The system incorporates all the measures in Flood System 1 to ensure that the internal walls dry rapidly and can be redecorated quickly.

Flood System 3 boosts the level of protection to the internal walls by application of a cementitious tanking product that provides waterproofing at negative pressures up to 5 bar. This can be applied up to 0.6m to stop flood water getting into the premises and is particularly suitable where very low-level flooding (<0.3 m) is expected.

When considering the right combination of measures and products, it may be necessary to get specialist advice from a consultant or from the technical team of a supplier, such as Safeguard. As with any system designed to protect from or manage water, it is vital to get the detail right at the design and installation stages.

> Download Safeguard's guide to flood resistance, resilience and water entry